Raman spectroscopy is a powerful and increasingly ubiquitous analytical tool capable of identifying molecular constituents of samples under test and, when combined with microscopy, exploring specific cellular structures and functions. Non-invasive, non-contact, requiring no sample preparation or chemical tagging – it is no wonder that Raman has established a presence as an invaluable analytical technique both in labs and in the field.

The exchange of energy between photons and vibrational modes of molecules that defines Raman scattering occurs for approximately one in a million incident photons. This exchange in energy between incident photon and molecule results in a shift in wavelength of the Raman scattered photon relative to the excitation wavelength, either a “Stokes” shift to lower energy, longer wavelength or “anti-Stokes” shift to higher energy, shorter wavelengths. The low probability of this event makes detection of this informative, but elusive, Raman scattered signal from the dominant Rayleigh scattered photon signal like finding a photonic needle in a brightly illuminated haystack. This is where optical filters enter the story; wavelength selective optical filters can be used to block the dominant Rayleigh scattered light and transmit only the Raman scattered photons providing “more signal, with less background” to the detector. However, in order to appropriately balance the technical (performance) and commercial (cost and supply) needs of different markets and applications different optical filters are required, striking the balance between filters with steeper slopes and smaller cutoff values for cutting edge technical performance but at higher cost and another lower cost family of filters with larger cutoff values and wider angle tolerances that enable the use of lower cost laser sources and compact lower cost optics used in high volume, low cost instruments to clearly identify the molecules being investigated.

Details matter – High precision Raman

Raman analysis has been recognized to have the potential to identify the molecular make-up of many unknown different chemicals including drugs and pharmaceuticals (along with their counterfeits). The signature Raman spectral “fingerprints” of chemical species can be observed using high precision, analytical laboratory tools such as Confocal Raman Microscopes, critical in research environments. However, many of the details that make this molecular species identification possible are associated with small energy exchanges between the incident and Raman scattered photons. As a consequence, access to this “fingerprint” region of the Raman spectrum requires detection of the Raman signals extraordinarily close to the laser line wavelength and thus requires extremely steep edge pass filters with accurate “cutoff” wavelength positions filtering.

“Cutoff” is defined as the spectral shift in wavenumbers (cm-1) between an optical density blocking of six orders of magnitude at the laser line wavelength (OD>6 or <0.0001% of the laser line power) and the 50% transmission point. Key spectral information in this fingerprint region can reside within a cutoff of 25-50 cm-1, defining the requirement for detection in the Raman instruments.

This creates several challenges for optical filter manufacturers. First a filter needs to be designed with a steep enough edge slope to achieve in theory this extremely low cut-off value. This can require filter designs with as many as 100s of tightly controlled individual dielectric layers or more. Secondly, even with a filter designed and manufactured with a steep enough edge slope, the wavelength targeting and uniformity across the part size (often 12.5mm up to 25mm) present challenges to control the manufacturing processes to this level of wavelength accuracy in a repeatable, manufacturable manner to realize this performance in practice.

Is it this or is it that? – Handheld “in-field” Raman

In contrast to trying to identify completely unknown materials from their chemistry or using Raman microscopy to study material structures, Raman’s powerful ability to rapidly identify molecules non-invasively and without any sample preparation has created an explosion in demand for handheld/portable Raman analytical devices intended to identify molecules from a smaller library of possibilities. These portable precision devices include small desktop instruments used in applications such as airport liquid screening, instruments with handheld probe attachments for dock-to-stock analysis of incoming goods such as pharmaceutical shipments in barrels, and handheld devices which can rapidly detect and identify illicit drugs, precursor chemicals, explosives, gemstones, raw materials, additives, residues of pesticide and veterinary drugs.

In order to provide the versatility needed in “real-world” environments this family of Raman instruments requires the ability to scan materials with a wider incident angle of light (AOI) and possibly an uncollimated cone half angle (CHA)), along with the ability to, as a consequence, accept higher wave number, increased cut-off values for the detected Raman signal (a wider passband wavelength range for the filter) such as >250 cm-1 from the laser line. Extended operating ranges are often also required pushing the transmission band to longer wavelengths such as up to 1420nm or 1770nm (the lab units typically only operate between 300nm to 1200nm due to the Si detectors used with them).

These broad operating conditions create different filtering challenges than discussed above. While the filters are less complex in terms of layer count for the Raman edge-pass (due to the reduced steepness), they need to have controlled cut-off values to accommodate the broad angle ranges of use along with broad and deep blocking ranges. Additionally, these filters are far more cost sensitive as the instruments using them can be an order of magnitude less expensive than their laboratory cousins and they need to be able to be integrated into the instrument passively (that is with less manual alignment) due to the volume nature of these builds.

Optical Filter Solutions:

Clearly there need to be different optical filter solutions to address the needs of these to, related but very different market applications.

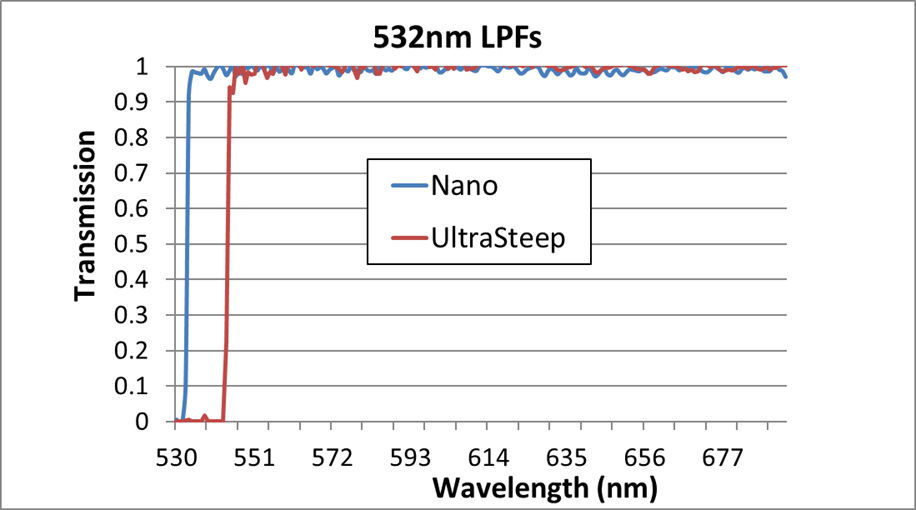

To address the needs of the high precision Raman instruments, Iridian is able to offer a series of ultra-steep long pass edge and “nano-edge” long pass filters (LPFs). The ultra-steep (US) LPFs have cutoff values in the range of 40-50 cm-1 whereas the “nano-edge” LPFs have cutoff values of between 25-38 cm-1. Due to the steep nature of these steep LPF filters, the end user’s system setup must have tight controls on AOI with a very well collimated input laser beam and well-known laser line wavelength in order to take optimal advantage of the low cutoff values that these filters are designed to provide.

Iridian’s wide angle long pass filters (WA LPF) are a preferred solution for customers’ instruments and devices with wider AOI ranges of 0-2 degrees, CHA up to 5 degree, and provide extended passband wavelength range with transmission > 93-95%, and extended blocking wavelength range with OD6 blocking over the broad operating ranges of these devices.

|

LPF types |

Laser Line [nm] |

AOI Range [degree] |

CHA [degree] |

Cutoff [cm-1] |

Blocking range [nm] |

Pass Band Tx > 93% Range [nm] |

Blocking (Optical Density) |

|

Nano |

785 |

0 |

0 |

26 |

785 |

789-1200 |

OD 6 |

|

US |

785 |

0-1 |

0.1 |

40 |

785 |

790-1200 |

OD 6 |

|

WA |

785 |

0-2 |

5 |

105 |

650-786 |

792.5-1200 |

OD 6 |

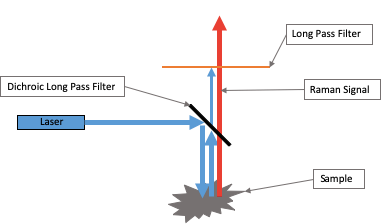

Often dichroic filters are also used in the Raman probe and spectrometer systems where they are used to reflect the laser to the sample and also as first edge pass filter together with the second edge pass filter in the instrument. As a result, the dichroics used in these cases also need to cover the extended transmission bands for the receiving signals.

In both types of Raman systems, narrow laser line filters are employed to clean-up the excitation source and block any secondary peaks from reaching the sample under test. These narrow bandpass filters need to be designed to pass the laser line while ensuring that the blocking aligns with the transmission band of the chosen edge pass filter to avoid laser light leakage into the detection path.

While there are many off-the-shelf standard filter solutions available, it is important to ensure that the right filter is being chosen for the right task to optimize the technical performance and minimize the price for performance. Custom filter solutions (or tailored versions of standard solutions) can often be the best choice especially for OEM instruments where volumes will run into the many 10s to 100s of units. By looking to optical filter vendors as partners or collaborators to help recommend and design the best solution for a given need these trade-offs and optimizations can be considered and designed in early, saving time and money and optimizing Raman signal output.

Iridian Spectral Technologies Ltd (Iridian) is a diversified optical filter manufacturer that is an international leader in filter design and manufacture especially for application in the fields of fiber optic communications, optical spectroscopy, 3D entertainment, and in aerospace. Iridian is a global supplier with distributors in many countries.