On Nov. 24, 1903, Clyde J. Coleman was issued a patent for an electric automobile starter. The 1912 Cadillac became the first car to replace the hand crank with an electric starter motor and, by 1920, electric starters were ubiquitous across all vehicle brands and models.

Much like vehicle hand cranks in their day, the use of a gain flattening filter (GFF) paired with a wavelength- division multiplexer (WDM) in optical fiber amplifiers – such as erbium-doped fiber amplifiers (EDFA) — has been accepted not because it is ideal, but because a superior solution had yet to be created. Until now.

This article explains what a Hybrid GFF is and how it works. It also details the advantages of using Iridian Spectral Technologies’ Hybrid GFFs in lieu of a conventional two-filter setup in EDFA and other optical filter applications.

How GFFs and WDMs Serve Optical Fiber Amplifiers

EDFA modules are commonly used in fiber optic communication systems to recover the optical signal after it has been transmitted over a certain distance. Traditionally, electronic amplification was used for this task, transferring the optical signal to an electrical signal, amplifying that signal, and then transferring the updated electrical signal back to an optical one.

However, EDFA modules (passive amplifiers) use an erbium-doped fiber to eliminate the need for transferring a signal from optical to electrical and back again. The optical signal is amplified within the fiber by a laser operating at a wavelength of 980 nm or 1480 nm, used to excite the erbium atoms, which then emit large numbers of photons when triggered by the much weaker incoming optical signal at the same wavelengths as the incoming signal. This results in an amplified version of the input signal at the output of the EDFA.

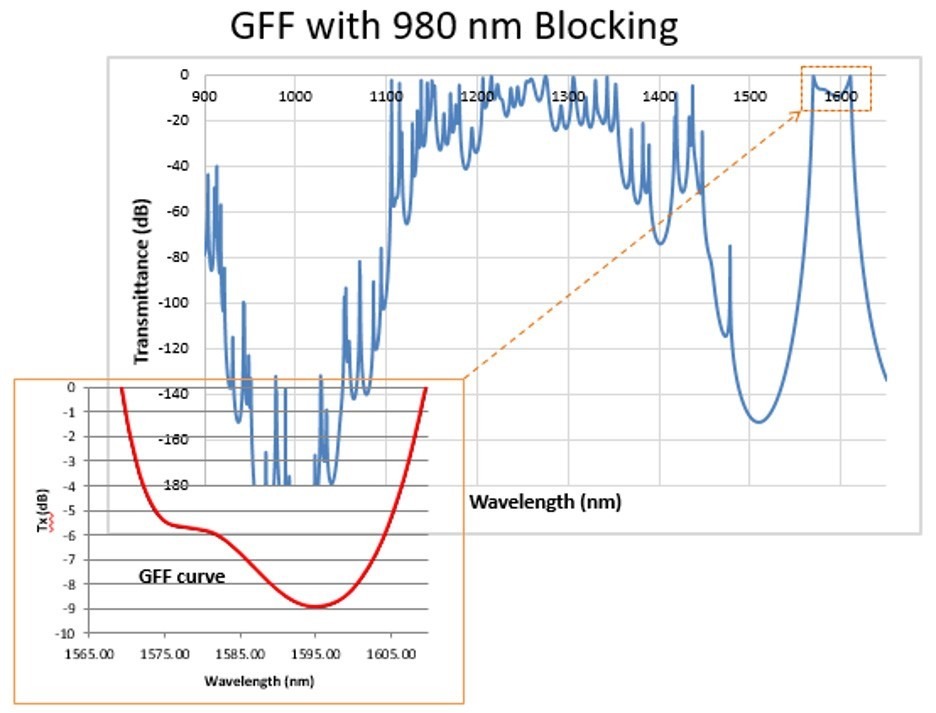

Most telecom wavelengths operate in the C-band (1520-1570 nm) or the L-band (1570-1620 nm), and the pump laser acting upon the signal will disrupt that precise wavelength – particularly problematic in a fiber accepting multiple communication channels.

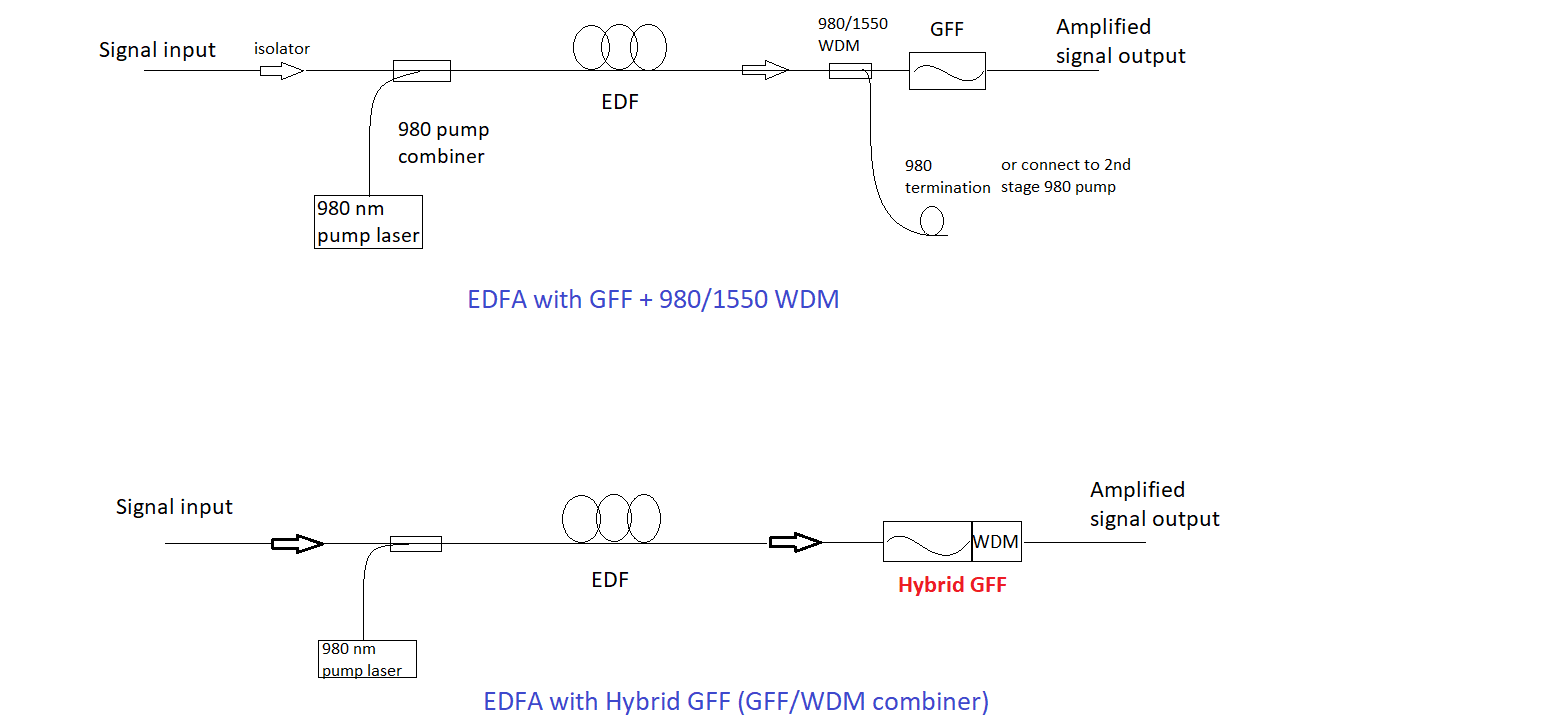

In traditional EDFA modules, a pair of filter components is applied to correct the EDFA’s output signal. A GFF is used to “flatten,” or even out, the outgoing amplified signal. This filter operates in tandem with a 980 nm-blocking (or 1480 nm-blocking) wavelength-division multiplexer (WDM), the latter used to minimize interference caused by the pump laser.

What is a Hybrid Gain Flattening Filter, and What Advantages Does it Offer?

Iridian Spectral Technologies has developed what is referred to as a Hybrid GFF, which combines the functionality of both a WDM and the GFF on one component. Specifically, a Hybrid GFF can block the pump laser from light in the range of approximately 980 nm or 1480 nm while providing gain flattening for signal light amplification — without the need for an additional pump wavelength blocking filter.

Moreover, a Hybrid GFF can be designed to pass or block other wavelengths in the 900 nm to 1700 nm band.

It’s vital to note that neither a base GFF nor a WDM is a trivial component from a design and manufacturing standpoint. So combining them into a single component that costs less than two separate filters – while accepting no compromise in single-band or multiband performance – is no mean feat.

The most obvious benefit of Iridian’s Hybrid GFF is substantial cost savings; a Hybrid GFF costs barely more than a base GFF while offering the functionality of two components. In addition to eliminating the cost of a separate WDM, use of a Hybrid GFF reduces system design complexity by cutting out a now-unnecessary element.

Related, eliminating the separate WDM leads to more compact dimensions for the EDFAs and other optical amplifiers overall, whether you’re trying to reduce equipment size or accomplish more within the same space.

In terms of quantifiable performance metrics, Iridian’s Hybrid GFFs excel, as well.

For example, GFF performance often is defined primarily by peak-to-peak error function (PPEF). Iridian, already known to produce base GFFs with extremely low PPEF, has empowered its Hybrid GFFs with this same industry-leading capability.

As with a base GFF, the deeper the modulation depth goes (i.e., the greater the variation in gain for which the component is needed to compensate), the more difficult it becomes to meet a customer’s desired PPEF. However, there is no performance compromise when upgrading from a base GFF to a Hybrid GFF.

Indeed, system designers implement a net performance gain when opting for a Hybrid GFF over a two-filter setup because they eliminate insertion loss between the two filters.

As a long-time contributor to the telecommunications industry, Iridian understands that new system designs are likely able to take better advantage of Hybrid GFFs, given the qualification cycle necessary to effectively launch a new technology or system in the field.

For example, a given batch of EDFAs will be produced from a spool of fiber that has been doped with erbium. Those draws of fiber have a specific gain profile, and a GFF must be designed to match that profile; this filter specification will be effective so long as the same draw of fiber is being used. But when new draws of fiber are produced, their gain profiles will differ slightly, necessitating the design and manufacture of new GFFs.

Thus, each replacement of optical amplifier components offers an opportunity for renovation; specifically, each new round of GFFs, designed to meet a target gain profile, offers an opportunity to improve the system and save money by implementing Hybrid GFFs.

Utilize Iridian Spectral Technologies’ Expertise

Iridian’s capability to accomplish Hybrid GFFs was born of its experience making optical filters that cover a wide market range, from spectroscopy filters and 3-D cinema glasses to space filters and mid-wave infrared (IR) filters. This diverse experience grants Iridian’s design team a more comprehensive design and manufacturing toolbox than competitors, informed by learnings from other market areas and design approaches.

If a supplier only completes the same task or makes the same part all the time, they aren’t exposed to other opportunities, other design philosophies, or other manufacturing strategies. Toyota’s Total Productive Maintenance (TPM) evolved into the now-universal lean manufacturing philosophy because other industries took notice of its effectiveness and adapted it to their needs. Iridian takes that same approach in its design for manufacture philosophy.

A good supplier can design anything, but you want a design that’s repeatedly manufacturable, over increasing volumes, without any decline in quality or deliverability.

By maintaining a strict inspection and quality control program in-house, Iridian can couple robust research and development with impeccable gatekeeping. Thus, if there are uncertainties to be resolved — especially early on in a new technology — they are discovered and remedied early, ensuring that every component shipped meets our commitments.

Further shoring up this quality and capability is Iridian’s proprietary software. The coding is constantly revised and improved — in-house, not outsourced — to seamlessly apply the same software used to design components toward controlling deposition equipment, creating a feedback loop that ensures successful results. Repeatable successful results.

Finally, keep in mind the nature of a strategic partnership. Transactional supplier relationships are perfectly appropriate for common, well-understood components that leave little room for innovation. Strategic supplier partnerships, though, embolden a company’s requests to evolve beyond “build this optical filter, this way,” to “here’s what my system does; how can you help?” Iridian is committed to being just such a solutions provider, rather than simply a component supplier.

Conclusions

Using an Iridian Spectral Technologies Hybrid GFF allows system designers to maximize cost effectiveness, capability, and system simplicity in one fell swoop. Every company’s performance and cost demands are different, so you need a supplier with the experience, technical knowledge base, and flexibility to adapt to your systems’ and business’s changing needs.

Just as the electric car starter eclipsed the engine hand crank, a superior option has emerged for optical signal filtering that will redefine how system design is approached. The only real decision is whether you’ll be an early adopter, or rush to catch up later.

About The Authors

Xiaolun Zeng has a B.ENg in Automation Technology, an MSc. in Applied information and Computer Science, and more than 20 years’ experience assisting customers with a wide range of technology needs for telecommunications applications. Prior to joining Iridian in 2005, Xiaolun served as R&D and sales & marketing manager at Broadex; he also served in senior engineering, product development, and sales roles at AFOP, Santec, and JDS Uniphase. As Account Manager at Iridian, Xiaolun assists our telecom customers with optical filter solutions.

Michelle Derouin received her BASc in Electrical Engineering at Queen’s University in 2005 and is a Senior Application Engineer at Iridian Spectral Technologies with over 15 years’ experience in optical filter design. Michelle specializes in telecom filter design — Gain Flattener Filters and Dual Band Filters, in particular. Her skills and abilities in these areas have translated to a variety of product lines including 3D cinema production.

Iridian Spectral Technologies Ltd (Iridian) is a diversified optical filter manufacturer that is an international leader in filter design and manufacture especially for application in the fields of fiber optic communications, optical spectroscopy, 3D entertainment, and in aerospace. Iridian is a global supplier with distributors in many countries.