Clear the Air: New Optical Filters for Sensors and Detectors

Environmental air quality; proximity control; crowd counting; climate change; the “Internet of Things”. Our world has become an increasingly monitored place where the proliferation of sensors and detectors allows us, and our devices, to better understand and interact with our environments. Photonics is one of the key technologies enabling this growth, facilitating the development and commercialization of low-cost, compact, and robust optical sensors and detectors.

All optical sensors and detectors fundamentally operate in a similar manner;

- a light source illuminates the sample of interest

- the sample interacts with the light through absorption, reflection, transmission, or an energy exchange phenomenon such as fluorescence or inelastic (Raman) scattering

- the output from the sample is received at a detector

In order to discriminate the analyte of interest, wavelength selectivity must be enabled at the illumination source, the detector, or in some cases, both. Multi-layer dielectric optical filters are a passive, robust, highly selective, and economical means of providing wavelength selectivity to these optical sensor/detectors.

Optical filter technology has seen an evolution in durability, filter shape complexity, and cost to address needs in the VIS/NIR/SWIR wavelength range. Modern, energetically sputtered coating technology engineers optical filters to meet stringent environmental and lifetime requirements without relying on lamination to protect them from the elements and without an expectation of having to be replaced as they wear out and fade. As sensors and detectors are most often employed in “real-world” rather than laboratory environments, durability and reliability of optical filters is a “need-to-have” rather than a “nice-to-have” parameter.

Detectors employed in the mid, and long-wave IR (MWIR: 3-5µm/LWIR: 8-12µm), once the domain of only the military and defense industries, have become increasingly commercially viable as their costs have decreased. This has helped drive the demand for optical filters for commercial applications in markets such as surveillance, security, industrial process control, environmental monitoring and analysis, and medicine, and has created a new set of requirements for optical filters.

The successful production of optical filters with increasingly complex optical performance providing improved signal-to-noise and multi-band spectral performance has been facilitated by the development of in-situ optical monitoring and automated coater control with dynamic design adjustment. Coupled with improvements in coater uniformity and efficiencies of machine operation through load-lock systems, these “state-of-the-art” deposition technologies have reduced filter manufacturing costs at the same time as the complexity of the filters produced has increased.

Gas detection: Non-Dispersive IR (NDIR) and Photo-Acoustic Spectroscopy (PAS)

Detection of the presence and concentrations of specific gas molecules has value in many applications and markets:

- industrial process monitoring (such as combustion or food spoilage) – CH4, CO2, CO

- automotive exhaust or cabin air quality – NOx, CO2

- building air quality/safety – Formaldehyde, CO

- medical/health gas monitoring in anesthesiology, sleep apnea, breathalyzers

- flame detection

- motion sensing, crowd populations

Unlike electrochemical sensors, optical IR gas sensors detect the presence and concentration of these specific gas molecules and do not rely on chemical reactions. This results in improved longevity as they do not suffer from performance degradation over time.

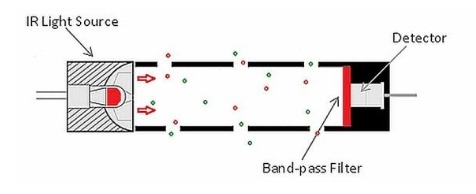

Non-dispersive infrared (NDIR) sensors are relatively simple optical devices consisting of an IR source, a gas sample, and a detector (see figure 1). The presence of a wavelength selective optical filter situated in front of the detector is a key component in determining the gas to be detected.

Figure 1: Illustration of NDIR gas detection system

Figure 1: Illustration of NDIR gas detection system

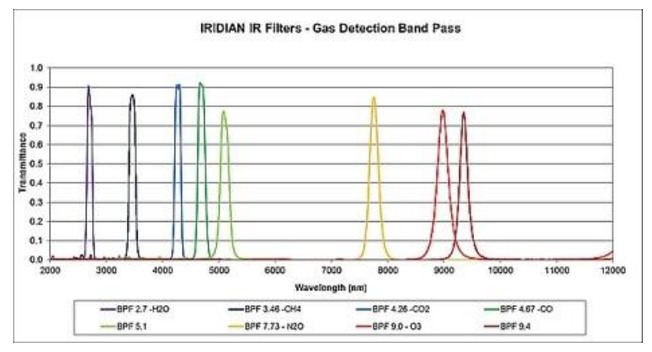

IR light incident on the gas will be absorbed according the unique spectral “fingerprint” associated with the gas molecule that is present (see Table 1). Optical filters with a band-pass region corresponding to the peak absorption band of a selected gas (or gases) result in the intensity of filtered IR light reaching the detector depending only on the concentration of the chosen gas.

Table 1: Mid and long wave infrared gas absorption peak wavelengths

| Gas Molecule | Peak wavelength (µm) |

|---|---|

| H2O (water) | 2.7 |

| CH4 (methane and other hydrocarbons) | ~3.3-3.5 |

| CO2 (carbon dioxide) | 4.26 |

| CO (carbon monoxide) | 4.67 |

| NOx (nitrogen oxides) | ~5.3 |

| N2O (nitrous oxide) | 7.73 |

| O3 (ozone) | 9.0 |

In the absence of the gas of interest, the intensity will match a reference level and in the presence of the selected gas the intensity at the detector will vary inversely proportionally to the concentration of gas according to Lambert-Beer’s law:

![]()

Where I is the intensity of light at the detector, I0 is the reference intensity (no gas present), k is the absorption coeffiecient constant for the system, and P is the concentration of the gas being measured.

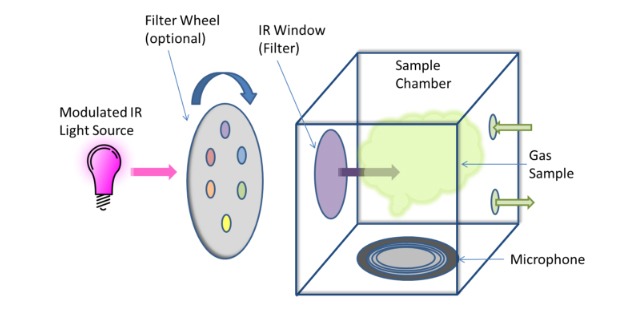

Unlike most photonic sensor technologies such as NDIR which employ both optical illumination and detection, in photo-acoustic spectroscopy (PAS) light is converted into sound by the sample gas. Gas in a sample chamber is excited by modulated MWIR light. Absorption of this light energy results in an increase in temperature and pressure of the gas under interrogation which in turn results in acoustic vibrations that can be detected by extremely sensitive microphones on the sample cell (see figure 2). This “photo-phonic effect” (the generation of sound by modulated light incident on materials) was discovered by Alexander Graham Bell in 1880 and described in the American Journal of Science—Third Series, Vol. XX, No.118, -Oct.,1880 in the paper “On the production and reproduction of sound by light” transcribing his reading before the American Association for the Advancement of Science.

Figure 2: Illustration of PAS gas detection system

Again Lambert-Beer’s Law applies with the exception being that rather than detecting a change in light intensity, the cell detects a power output from the microphone proportional to the number of gas molecules present (their concentration) and their absorption cross section for the excitation wavelength. A key advantage to PAS is that it is not a decrease in intensity of transmitted light that is detected, but rather an increase in microphone power from “zero-baseline” state. This makes these systems background free without the need for a reference signal.

Signal selectivity is achieved in these PAS devices by tailoring the wavelength of the illumination source to match absorption bands of specific gases of interest. Narrow band-pass filters (BPF) provide an economical and robust solution that can turn a simple MWIR broadband light into a monochromatic illumination source. This can manifest itself as either a wavelength selective window on the input of the cell (for sensing of a single specific gas) or as a filter wheel to allow different excitation wavelengths to be selected making the cell capable of sensing and detecting different gases of interest.

For both NDIR and PAS sensor systems, the optical filters used are similar to narrow emission band pass filters used for fluorescence detection and analysis in the visible wavelength range. Unfortunately the common metal-oxide dielectric coating materials and glass substrates commonly used in the VIS range are not transparent in the M/LWIR, and while there are many suitably transparent substrate choices for the M/LWIR (Si, Ge, sapphire, and ZnSe to name a few), historically available coating materials in the M/LWIR were often only able to be deposited by evaporation techniques resulting in less robust coatings. New sputtering methods capable of depositing IR transparent materials have enabled the production of robust optical filters. Additionally these sputtered materials allow durable coatings to be designed and deposited with narrow pass-bands (<5% of the center wavelength), high peak transmission (>70%), and broad blocking (UV-LWIR) to provide the high selectivity needed for detection of specific gas absorption lines.

Figure 3: Iridian M/LWIR gas detection band-pass filter curves

Historically, IR gas sensor systems have been more costly than electrochemical systems, but with increasing availability of low cost MWIR sensors and improvements and reduced costs, improved availability, and greater selectivity, durability, and affordability in MWIR “gas band-pass” optical filters the demands for NDIR or PAS gas sensors are expected to continue to experience significant future growth. New demands for these gas sensors will continue to emerge due to the proliferation of sensors in all aspects of society.

Remote sensing and multi-spectral imaging (MSI)

Despite the relative affordability of individual M/LWIR detectors, there are still applications in which a premium is put on optimizing the detectors and systems to analyze multiple different phenomena and constituents in a single device. Earth-observation instrumentation deployed in satellites for remote sensing of environmental characteristics must be optimized to meet allowed budgets for size, space, and weight with significant value placed on the ability to “fuse” the images of different time-varying phenomena to demonstrate relationships and dependencies between these phenomena. Optical engineers have addressed this challenge by coupling optical filters with spatially varying spectral performance (multi-zone filters) with a camera/detector, creating multi-spectral imaging (MSI) systems, minimizing cost and payload size, and providing “a snap-shot in time” image fusion of multiple analytes.

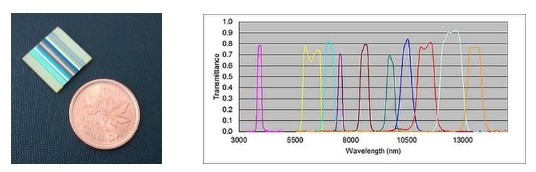

While multispectral imaging systems in the VIS-NIR can be constructed using photo-lithography processes to pattern the different spectral zones on a monolithic substrate in the M/LWIR, the coating thicknesses and different coating and substrate materials have presented challenges to this traditional approach to MSI manufacturing. Iridian Spectral Technologies has developed technology to assemble arrays from individual M/LWIR band-pass filters to address this challenge. Deposition processes and materials have been developed to enable production of robust spectrally selective individual filter elements (analogous to the gas band-pass filters described above). Through much experimentation and testing assembly techniques have been refined to produce durable and reliable arrays that achieve minimal pixel loss (well controlled optical zone sizes and minimal transition zones) while meeting environmental and mechanical requirements needed for instruments destined for space (radiation insensitivity, structural integrity, etc).

A recent example of application of this technology is shown in figure 4. Developed under subcontract from ABB-Canada for the Space Technology Development Program (STDP) of the Canadian Space Agency (CSA) this optic consists of ten different spectral bands in the M/LWIR all in a footprint the size of a penny.

Figure 4: M/LWIR filter array and spectral curves (developed under subcontract from ABB-Canada for the

Space Technology Development Program of the Canadian Space Agency)

The different spectral bands in this optic enable simultaneous imaging of cloud height, ozone levels, atmospheric ash, wind and humidity levels, fog, fires, and ice among others (3). New capabilities to measure and monitor these environmental characteristics, improving weather forecasting and climatology in the Canadian arctic, will be obtained when this technology goes into orbit later this decade (2017).

By leveraging the M/LWIR multi-zone filter or by combining these with VIS-SWIR filters, one can provide an even larger spectral coverage for other remote sensing applications in areas such as agriculture, forestry, tracking of the effects of natural or man-made disasters (volcanic ash clouds, forest fires) could be facilitated.

Mid IR Bandpass Filters

Iridian’s SWIR, MWIR and LWIR bandpass filters are designed to optimize detection of spectral emission lines.

These filters are deposited using energetic sputtering, which makes them very hard and durable.

- Reliability as per MIL-C-48497A

- RoHS compliant